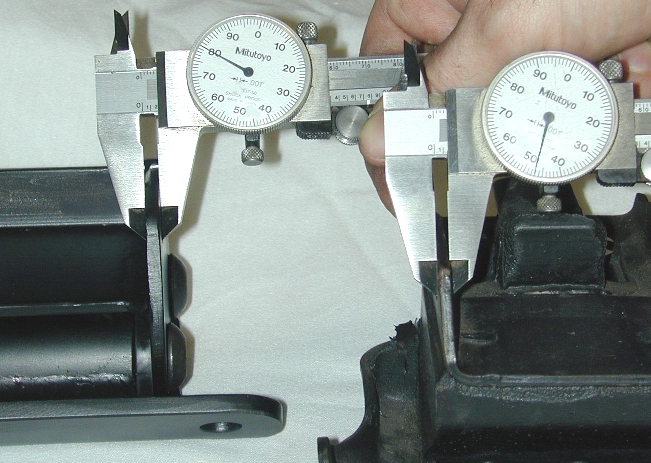

ConstructionExtra material = extra strengthThe picture below shows how much thicker our new poly mounts are compared to the stock mounts. The new side plates, which are being measured, are approx. .175 thick, and the stock side plates are only .145. The main base plate on the new mounts measure .245 thick, and the stock base plate is only .145 thick. We also measured a pair that was not OEM from a reputable auto parts supplier, and they were only .125 thick, which is almost 1/8" difference! Another improvement we made was to add more material around the mounting bolt holes, where strength is critical. Once you have them in your hands, you can tell immediately why we say they are virtually indestructable. |

||||||

|

|

||||||

How are they welded together? We use a state-of-the-art high frequency mig

welder with a special blend of gas, enabling us to get the strongest

weld with the best possible penetration. This is the same

equipment that is used to weld hydraulic cylinders that are tested at

over 5000 psi. They are tacked together before welding in several

different CNC machined fixtures to ensure a perfect fit every time. More quality components The tubes are made to exacting tolerances from

1026 DOM tubing, ensuring a great fit. The bushings are made

of the best polyurethane material available that will resist gas, oil,

and ozone conditions. Through the center of the bushings is

another tube that is CNC threaded, and sized to allow the perfect

clearance. This allows the mount to work correctly with no

unwanted movement or flex, and it is also noise and maintenance free. |