We

are now a dealer for the line of Remflex Performance gaskets. We use

these on our own GN and they work great. Currently carrying header

gaskets for stock heads, 3 bolt turbo flange gaskets and

external / internal wastegate downpipe to turbo gaskets.

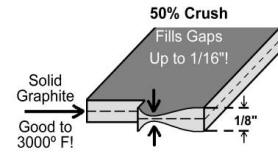

• Seals Warped Flanges:

Remflex

exhaust gaskets come in a standard 1/8-inch thickness and are designed to

crush 50%. This allows them to fill gaps in the flange surface up to

1/16-inch!

• Won’t Burn Out:

100% flexible graphite

construction means Remflex gaskets are good for up to 3,000 degrees

F—far exceeding that of any vehicle’s exhaust system temperature!

• No Re-Torquing

Necessary:

Remflex exhaust gaskets

rebound 30%, creating an optimum seal that eliminates the need to

re-torque!

Remflex’s

unique flexible graphite material has been proven for more than 30 years

in industrial applications, where temperatures routinely exceed 2,000

degrees—day after day, week after week, year after year. Now, we’re

bringing this technology to enthusiasts of all kinds to eliminate exhaust

leaks for good! Whether you have an old pick-up that needs a manifold

gasket, or a race car with custom-built headers, you can be assured that

Remflex exhaust gaskets will work properly the first time, every time.

Remflex’s

unique flexible graphite material has been proven for more than 30 years

in industrial applications, where temperatures routinely exceed 2,000

degrees—day after day, week after week, year after year. Now, we’re

bringing this technology to enthusiasts of all kinds to eliminate exhaust

leaks for good! Whether you have an old pick-up that needs a manifold

gasket, or a race car with custom-built headers, you can be assured that

Remflex exhaust gaskets will work properly the first time, every time.

The

Science

Remflex

gaskets work because they solve the two main problems associated with

sealing an exhaust flange: Warping, and gasket failure.

Warped

Reality

A

common misconception is that, if you spend a lot of money for high-quality

headers with thick flanges, leaks will not be an issue. In truth, a

thicker flange does help, but it can’t solve the problem of warping

altogether. Constant thermal cycling, especially in high performance

and/or high-load environments, causes warping of header flanges and cast

iron exhaust manifolds--even the exhaust flange of the cylinder head

itself.

A

common misconception is that, if you spend a lot of money for high-quality

headers with thick flanges, leaks will not be an issue. In truth, a

thicker flange does help, but it can’t solve the problem of warping

altogether. Constant thermal cycling, especially in high performance

and/or high-load environments, causes warping of header flanges and cast

iron exhaust manifolds--even the exhaust flange of the cylinder head

itself.

Once

the sealing surface is warped, leaks are imminent—and once there is a

leak, pitting of the exhaust port sealing surface usually follows. A new

set of average gaskets won’t fix the problem—but Remflex gaskets, with

a 50% crush built in—can seal gaps as large as 1/16-inch. And unlike

traditional gaskets, they won’t shrink, so they never require re-torquing.

If

you can’t take the heat…

Curiously,

the number one cause of exhaust gasket failure is heat—the very thing

exhaust gaskets are supposed to withstand. That’s because traditional

exhaust gaskets are made of composite materials—blends of natural fibers

and synthetic compounds that are bound together using rubber. Simply put,

it’s only a matter of time until the extreme temperature in the

vehicle’s exhaust system burns the gasket’s composite materials away,

resulting in an exhaust leak.

You’ve

no doubt experienced the pungent odor that arises from the engine

compartment after you install a new set of the top-brand exhaust gaskets.

That’s the smell of the rubber binders in the composite materials that

begin to burn out almost immediately. And once the rubber overheats, it

begins to shrink, as well has harden. That’s why you are instructed to

re-torque the gaskets regularly, and why an exhaust leak will develop if

you don’t. Remflex exhaust gaskets are made from 100% flexible graphite

and can withstand up to 3,000 degrees F—so they are not affected by

exhaust system, and won’t burn out, shrink, or leak. Not now, not ever!